triaxial cell permeability test|quick triaxial testing : distributors This paper provides an introduction to the triaxial test, explaining why the test is performed, the stress state of a tested soil, required test system components, and the general procedure for . Carpeta Pedagogica Digital - Udabol. Carpeta Pedagogica Di.

{plog:ftitle_list}

WEB72.017 Imagens gratuitas de Homem Perfil. Imagens sem direitos de autor. homemretratomacho. homemretratomodelo. retratomachofumar. homemretratoperfil. .

The triaxial, falling head permeability test should be conducted at a gradient that results in an applied effective stress at the outflow end of the sample less than the preconsolidation stress of the material.

The new design has the advantages of both conventional Hoek cells (e.g., minimal .

what is triaxial testing

triaxial testing methods

The triaxial, falling head permeability test should be conducted at a gradient that results in an applied effective stress at the outflow end of the sample less than the preconsolidation stress . Define what is triaxial testing. Outline why you should perform these tests. Explain different types of triaxial tests and methods. Go through the typical test procedures. Explore details of the main components required. Go .This paper provides an introduction to the triaxial test, explaining why the test is performed, the stress state of a tested soil, required test system components, and the general procedure for .For lower permeabilities, usually when checking that the material is impermeable enough to meet a specification, the Triaxial Permeability is a more appropriate test. K H Head Method Description

Triaxial Testing. Soil triaxial testing is a fundamental procedure in geotechnical engineering, used to determine a sample’s shear strength parameters. During triaxial testing, a cylindrical soil sample is enclosed in a rubber membrane and .Permeability Cells (Flexible-Wall): Humboldt's HM-4188B Permeability Cells and our HM-4199B Triaxial Cells can be used to measure hydraulic conductivity (permeability) of soils using .A simple triaxial cell is described together with details of the technique employed for triaxial testing. Triaxial strength results for 254 specimens of eight rock types are tabulated. The . The new design has the advantages of both conventional Hoek cells (e.g., minimal preparation and setup time) and conventional triaxial systems (e.g., on specimen radial .

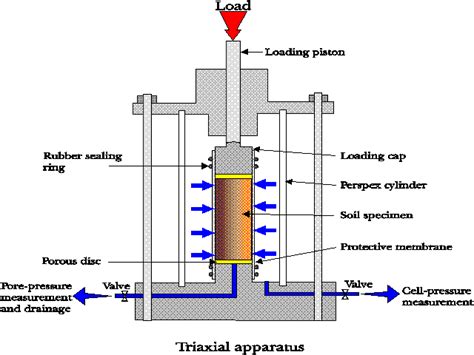

of a triaxial specimen inside a triaxial cell is shown in Figure 2. Figure 2 – General set-up of a soil specimen inside a triaxial cell. What are the types of triaxial test? There are three primary triaxial tests conducted in the laboratory, each allowing the soil response for differing engineering applications to be observed. These are:The permeability cell is similar to a triaxial cell; it has interchangeable base pedestals to accomodate specimens of various diameters, is equipped with double drainage lines to the top and bottom of the test specimen, and can accomodate a differentially acting pressure transducer to measure head loss across the soil specimen.Humboldt's HM-4188B Permeability Cells and our HM-4199B Triaxial Cells can be used to measure hydraulic conductivity (permeability) of soils using several methods as described in ASTM D5084. . pressurized test cell (either permeability or triaxial cell). These cells use a system of valves and burettes mounted on a distribution panel, like our .

The Triaxial permeability method is undertaken with a constant hydraulic gradient, using automated pressure controllers to maintain confining pressure, inlet pressure and outlet pressure and to measure the volume change. Constant Head Permeability Test (AS1289.6.7.1) Samples are prepared and remoulded in a rigid cylindrical cell.Triaxial Cells offer solid performance with Load Frames and Master or Auxiliary Control Panels in testing shear strength and stress-strain relationships of soil specimens in accordance with ASTM and AASHTO standards. Undisturbed or remolded soil specimens can be tested as required by the test method. Click here for a diagram that indicates a Triaxial/Permeability typical set-up .Triaxial Testing Equipment. Triaxial testing measures a variety of mechanical characteristics within soils. By simulating stress conditions, a pressurized cell is able to determine the shear strength properties of a sample. To perform a test, an undisturbed specimen (usually 38mm to 100mm) is saturated, consolidated and then sheared.

Triaxial Test Cell Accessories are required and are available as individual items or a kit. Kits contain porous stones, latex membranes, cap and pedestal, and O-Rings corresponding in size to the test specimen. . The Vacuum Pump applies vacuum pressures for specimen saturation phases and deairing of water for triaxial and permeability testing. 4. Testing Procedure for Permeability in a Triaxial cell using Clisp Studio. This test refers to the Constant head permeability method. At the time of writing, VJ Tech complies to BS1377-6:1990, EN ISO 17892-11 and D5484-16 (Method A). a. Sample Preparation. The preparation of the soil specimen should be made according to the testing standard.The Mohr-Coulomb failure criterion states that the shear strength of soil at failure (τ) is equal to:. τ = c + σ ∙ tanφ (6) Where: c is the soil’s cohesion. σ is the normal stress. φ is the angle of internal friction Hence, when more than one tests are conducted on the same material, utilizing different cell pressures, the various critical Mohr’s circles that are formed at failure .Triaxial / Permeability Control Panels regulate and measure air and fluid pressures in Test Cells during permeability and triaxial testing. For testing one specimen, the Master Panel with digital pressure readout is required. To test an additional sample simultaneously, a Basic Panel can be used and connected to the Master Panel to share .

triaxial testing guide

3.1. Triaxial cell and base. The apparatus has a maximum working pressure of 1700 kPa, which is much higher than the pressure required in this study.The designs of the ceramic disks, pedestal, top cap and triaxial base, as described in Fredlund and Rahardjo (1993), were modified to accommodate the specimen of 50 mm in diameter for the unsaturated .Traditional passive triaxial cells (known as passive due to the fact that they are used with an external actuator such as a load frame to apply axial loads), large diameter triaxial cells (up to 500mm sample diameter), active triaxial cells (based on Bishops and Wesley’s original hydraulic stress path apparatus and include an actuator ‘built in’), as well as cells specifically designed .Features. Expandable solution, suitable not only for standard triaxial testing (effective/total stress) but also for other type of soil testing; PC software for remote calibration of the channels and fully comprehensive data acquisition management; Multiple and flexible triaxial configuration (e.g. one frame and three cells) to perform simultaneously saturation, consolidation and monotonic shear; Triaxial Cell – The Triaxial cell comes in a range of sizes and pressure ratings. The cell contains the triaxial specimen and is pressurised throughout the test. Pore Pressure Transducer – In CU and CD triaxial tests, the pressures inside the sample are measured (U – Pore Pressure). This is done using a pressure transducer attached to the .

It Has Been Suggested that a Triaxial Shear Test Chamber Can Be Used to Measure the Permeability of Low Permeability Soils. to Verify This, the Influence of a Number of Test Parameters on the Measured Coefficient of Permeability Was Investigated. Results Indicate Such Permeability Tests Should Be Performed on Samples Having a Minimum Diameter of 71. 1 .Such a procedure would be referred as polyaxial or true triaxial test. Moreover, research has shown that the effect of the intermediate stress is minor. The principal stresses applied during a triaxial test are presented in Figure 1. .

The complete test system includes: Triaxial cell with accessories for 38, 50, 70 or 100 mm specimens Pressure control panel, three pressure lines (Go to Triaxial -Pressure systems) De-airing water system and accessories. The permeability cells .

1.3 Triaxial test to determine the shear strength of a . in particular low permeability samples need a long time to drain and adjust strain to stress levels. Consolidated undrained (CU) . sometimes requiring special load cells capable of handling higher pressures. Unconsolidated undrained. In an 'unconsolidated undrained' test, the loads . A more robust, but very time-consuming way to derive an appropriate loading/strain rate for CU tests is a series of triaxial tests which utilizes rates that vary one order to two orders of magnitude (e.g. 10 −6 s −1, 10 −7 s −1, and 10 −8 s −1). Such a test series requires full saturation of the specimens.Range of Triaxial Cells: GDS have a range of different sized cells available for permeability testing. Specimen sizes range from 38mm up to 150mm in diameter. Interchangeable Pedestal & Topcap: This reduces the costs when changing specimen sizes that are still supported by the chosen cell. Configurable set-up: Permeability of soil; There are many advantages to using triaxial tests in engineering. First, they are relatively simple and quick to perform. Second, they produce reliable and repeatable results. . a soil sample under a variety of stress and drainage conditions in a triaxial unconsolidated undrained compression test. In a triaxial cell .

The design of the cell ensure vertical alignment of the cell ram by clamping the Perspex wall separately from the cell top. 28-WF4050: Banded triaxial cell for up to 50mm dia. sample sizes, maximum working pressure up to 3500 kPa 28-WF4070: Banded triaxial cell for up to 70mm dia. sample sizes, maximum working pressure up to 3500 kPaTriaxial Control Panels regulate and monitor air and fluid pressures in the Test Cells through a system of burettes, valves, and regulators, and can also be used for hydraulic conductivity/flexible wall permeability testing of soils. Master or Auxiliary Control Panels offer greater flexibility to set up your system.At PSL we test permeability by the triaxial method in accordance with industry standards and best practices. Samples are placed into a triaxial cell and encased in a rubber membrane (flexible wall). The cell is then filled with water and once connected to the pressure unit the sample is saturated and pressurised. Data Analysis and Reporting

permeability first, cyclic triaxial test afterwards using the same cell. When the permeability and pore water pressure ratio values are plotted, a linear relation is determined.

triaxial shear permeability

Vol. 25, No. 6 WATER PERMEABILITY, TRIAXIAL CELL, HIGH PERFORMANCE CONCRETE 1203 Test Results Concrete specimens were tested after 12 to 16 months of either water curing or air curing at 23°C. All the experiments were carried out on three replicates and the average of the three results is reported. . The total test time for permeability . Permeability test results obtained with triaxial cell VLAŽNOST UZORKA (Moisture content) w=33% Flow-pump test apparatus (Institute of Civil EngineeringICE, Zagreb)

triaxial permeability testing

testing triaxial cells

quick triaxial testing

Casino Bonus. Baji Live is the most popular online gambling site primarily providing sports betting and casino services in Bangladesh and India. The brand has expanded its .

triaxial cell permeability test|quick triaxial testing